New generation of Chemical Thermal Mechanical Pulping (CTMP) process technology.

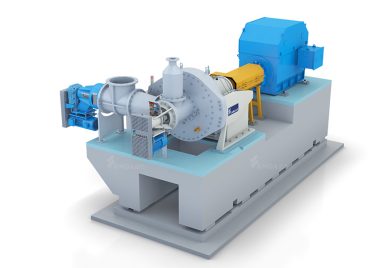

Yunda’s i-CTMP pulping system is an new generation of Chemical Thermal Mechanical Pulping (CTMP) process technology. Compared with the traditional CTMP process, i-CTMP has many advantages, such as lower investment cost, better flexibility with variations in raw materials, good pulp quality and low production cost.

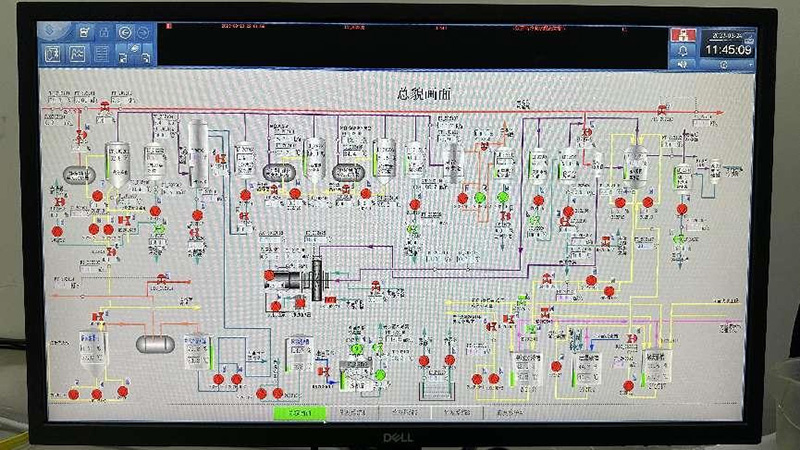

Raw materials like chips, first enter Chip Receiving Bin via Cabin Feeder, and are then discharged via Metering Screw into Chip Washer where sands and dirties are removed. After the washer, the chips are pumped into a Dewatering Screw to remove the excess water. The dewatered chips are sent to a Pre-steam Bin to be steamed and moisturized, and then conveyed to a Plug Screw Feeder via another metering screw before being fed into Pre-Heating Tube. The Plug Screw Feeder helps to form a stable plug and seal high pressure saturated steam inside the Pre-Heating Tube, where the chips are softened. The softened chips then enter a equalizer bin before being fed into Thermal Shredder system.

Optimization Run of the 400t/d Bamboo Fiber i-CTMP Project

In August 2023, Yunda project team went to the project site again to assist the customer in optimizing the operation of the 400t/d bamboo fiber i-CTMP project.

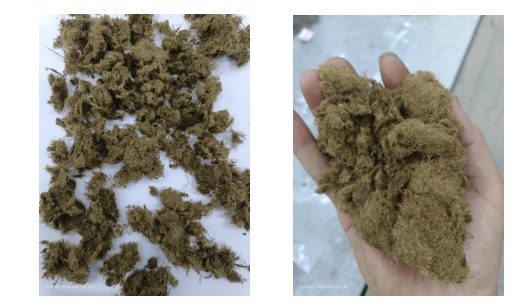

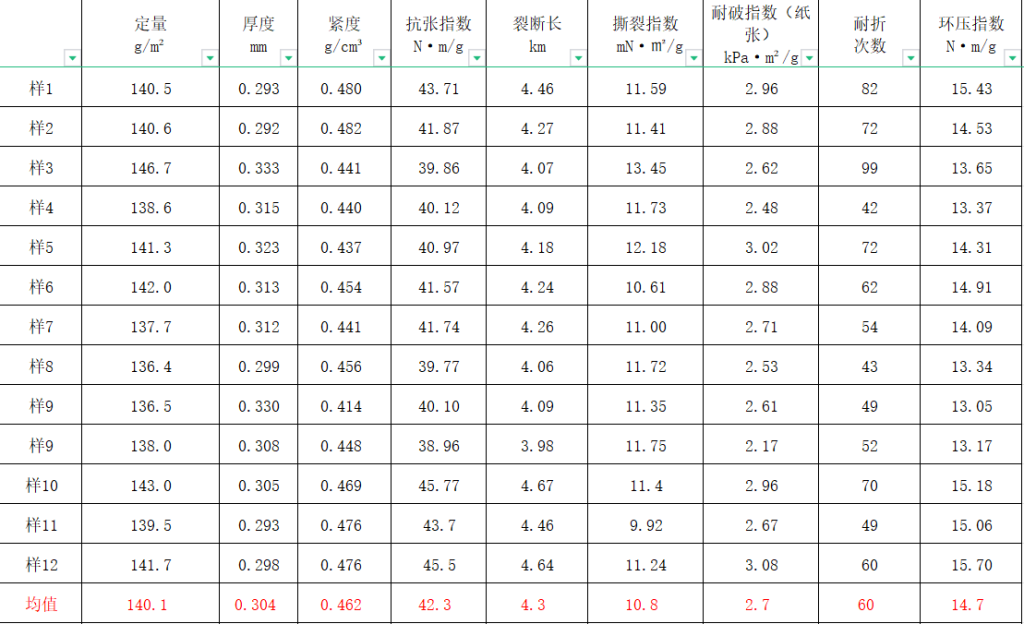

Customer’s Quality department conducts measurements of the pulp samples.

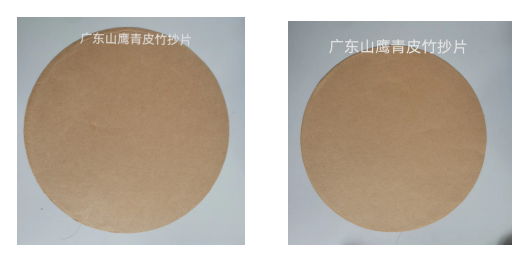

Customer used this time the bambusa texlitis as the raw material, and the quality of the pulp produced is close to the AOCC with long fiber.

The excellent process design of Yunda i-CTMP and key high-performance equipment such as thermal shredder, as well as the whole process of installation, commissioning and operation services have ultimately achieved the goals of better flexibility of raw materials, excellent pulp quality, and low production costs for customers.

Customer has given high praise to Yunda's technology, equipment and services!

After the start-up was completed, Customer organized a meeting to discuss the results of the start-up and items to be optimized.

Learn more i—CTMP