Raw material souce analysis:

Fiber and Debris

Ash

Rejects

- Plastics

- Wires & Strings

- Metals

- Non-Ferrous Metals

- Sand, Stone & Glass

- Stickies

CONTAMINANTS

- 1.5 - 2.5% LARGE LIGHTS

- PLASTIC & STYROFOAM

- 0.75 - 1.0% SMALL HEAVIES

- GLASS, GRIT, SAND, METAL

- 0.15 - 0.30% LARGE HEAVIES

- JUNK

- 0.5 - 1.5% STICKIES

- WAX, ADHESIVES, OTHER HOT MELTS

FURNISH SPECIFICATIONS

- 573 CSF (21.1 SR)

- 3.24% ASH

- BAUER MCNETT

- 32.8% - 14 MESH

- 20.7% - 28 MESH

- 16.6% - 48 MESH

- 11.4% - 100 MESH

- 18.5% - FINES

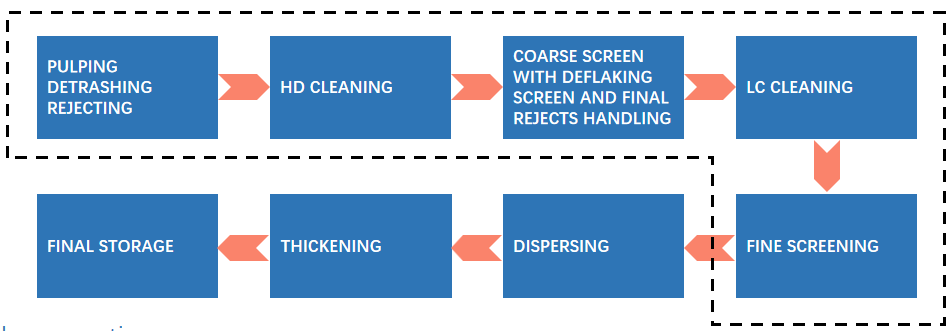

GENERAL PROCESSES

In the meantime…

GENERAL OCC LINE DESIGN CRITERIA

Perfect Quality of the Finished Stock

Constant Stability

High Yield

Easy Operation

Fast and Auto Start/Stop of the Entire System

Low Water Consumption

Low Power Consumption

Low Overall Investment Cost

Designing according to these principles, we will finally get:

High Paper Machine Runnability

Low off-grade Production Rate

Low Operation Cost

Finally,

High Profitability of the Paper Mill

Case

-

Five Continents Special Paper 450,000 tons packaging paper Project

Five Continents Special Paper 450,000 tons packaging paper Project

-

The i-CTMP High Yield Pulping Production line of Shan Ying

The i-CTMP High Yield Pulping Production line of Shan Ying

-

Shandong Tianhe i-BCTMP pulping line upgrade project

Shandong Tianhe i-BCTMP pulping line upgrade project

-

Guangxi Sun Cultural Paper

Guangxi Sun Cultural Paper

-

Qianan Boda Cultural Paper

Qianan Boda Cultural Paper

-

Vietnam Thuận An Paper PM8 Project

Vietnam Thuận An Paper PM8 Project

-

EG-Paper Packaging

EG-Paper Packaging

-

400t/d Bamboo Fiber i-CTMP Project

400t/d Bamboo Fiber i-CTMP Project

-

Guangxi Kebao ZDG425 Drum Pulper

Guangxi Kebao ZDG425 Drum Pulper

-

The Rebuild of IKPP OCC Line

The Rebuild of IKPP OCC Line