Structure

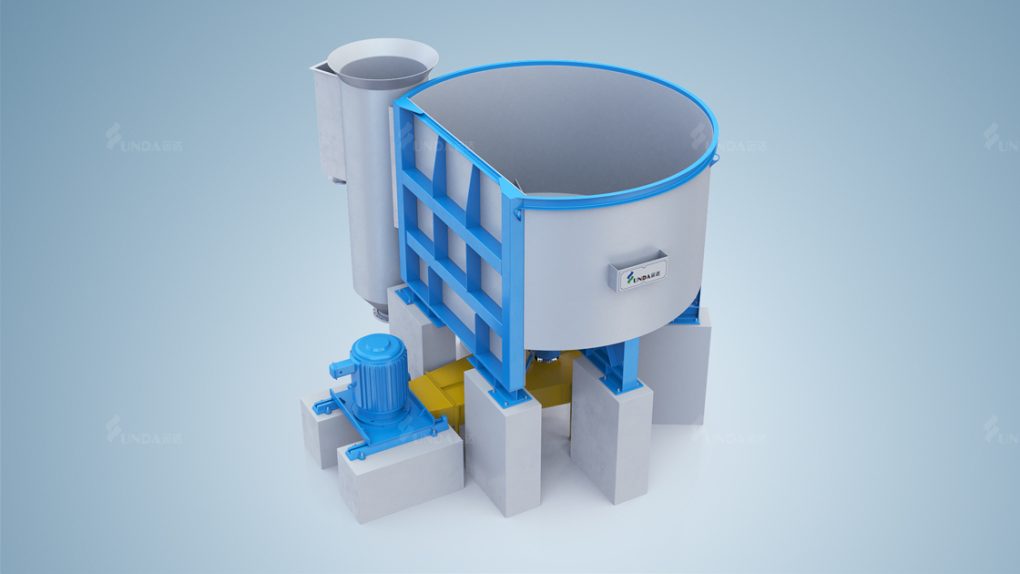

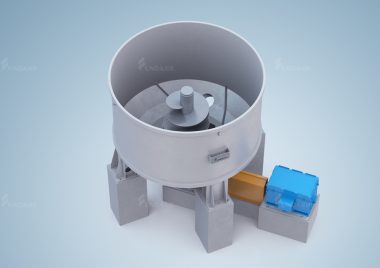

The pulper is composed of D type vat, rotor, screen plate, rack, motor and protective cover.

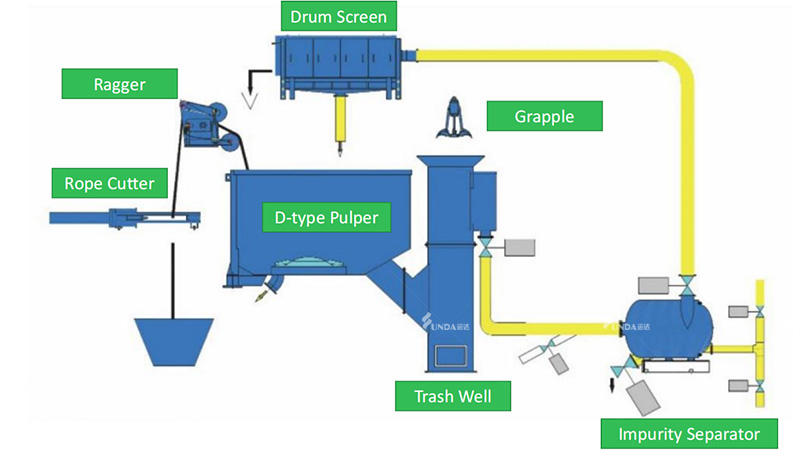

The continuous pulping system consists of D type pulper, Trash Well, Detrasher, Drum Screen , Ragger, Rope Cutter, Trash Well and Grapple, etc., the whole pulping process is controlled by the DCS automatic control system.

i-OCC (Low Consistency Continuous Pulping) Stock Preparation System

Operating principle

The waste paper is conveyed into the D type pulper which is the main equipment of the low consistency continuous pulping system through chain conveyor. Special vat body design shortens the recirculation routes of the stock, and fastens the contact in between the rotor and stock, shortens the pulping time, and lowers the energy consumption;

The raised VOKES rotor structure avoids catching of the rope, reduces the friction between rotor and impurities, increases the lifetime of the rotor and screen plate, reduces the cutting of the impurities.

The twisty impurities such as iron wire, plastic, clothes, ropes, etc. that enter the D-type hydraulic pulper along with the waste paper continuously form a twisted rope, which is then pulled out continuously or timely by a automatically controlled ragger followed by a rope cutter driven by double hydraulic cylinders, After being cut into suitable lengths, the ropes are shredded and sorted to realize the reject classification and reuse.

During the pulping process, the stock which is equivalent to about 20% of the total pulp volume, entrains together with a large amount of light impurities and some heavy contaminants into the trash well through the discharge outlet on the vat body of the D-type hydraulic pulper, the heavy contaminants settled in the bottom of the trash well is grabbed out regularly by the grapple into the Washing Well to recover fibers, then the cleaned heavy reject is again grabbed out of the system by the grapple;

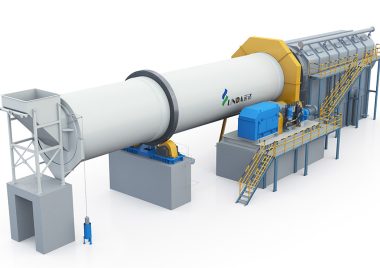

The light impurities with the pulp enter into the detrasher for further defibering, The accept stock goes through the screening plate and join together with Accept of the D type pulper, the remained impurities in the Destrasher enter into Drum Screen after washed by white water, and the recovered stock from the drum screen goes back to the pulper, the separated impurities are sent to the reject handling system.

Advantages

- The new energy-saving rotor improves the efficiency of the hydraulic recirculation and pulping, less power consumption.

- The D-type vat structure changes the stock flow, fastens contacts between rotor and stock, shortens pulping time, and increases capacity.

- Impurities in the continuous pulping system are removed in a timely manner, reducing the chance of impurities being finely broken.

- It is not required to stop the machine frequently to clean impurities, which improves the working efficiency of the entire pulping system and reduce power consumption

- DCS system control in the continuous pulping process to ensure accurate and continuous operation, strong pulping ability, excellent stock quality and high capacity.

Technical Parameter

| Model | ZDSD23 | ZDSD24 | ZDSD25 | ZDSD26 | ZDSD27 | ZDSD28 | ZDSD29 | ZDSD30 | ZDSD31 | ZDSD32 | ZDSD33 | ZDSD34 | ZDSD35 | ZDSD34 |

| Nominal Volume: (m3) | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 90 | 120 | 135 |

| Consistency: (%) | 44990 | |||||||||||||

| Capacity: (T/D) | 20-60 | 60-100 | 90-120 | 140-180 | 180-230 | 230-280 | 260-330 | 300-380 | 370-450 | 450-550 | 550-650 | 650-800 | 800-1100 | 1100-1500 |

| Motor Power: (kW) | 75 | 110 | 160 | 185 | 220 | 280 | 315 | 355 | 450 | 560 | 710 | 800 | 1000 | 1120 |

Project

- Annual Capacity: 280,000 Tons

- Paper Product Grade: Testliner, Fluting

- Raw Material: LOCC

- Add.: Xingtai City, Hebei, China

- Supply Scope: Chain Conveyor, D-Type Continuous Pulping System, HD Cleaner, MC Pressure Screen, etc.