Advantages

- Mainly used for washing and thickening low consistency pulp;

- Combined disk screen basket, greatly increase the filtering size, smaller floor area, larger capacity;

- Stainless steel screen cloth, longer service life;

- Rational washing structure, not easily blocked and strong dewatering capability

Structure and Principle

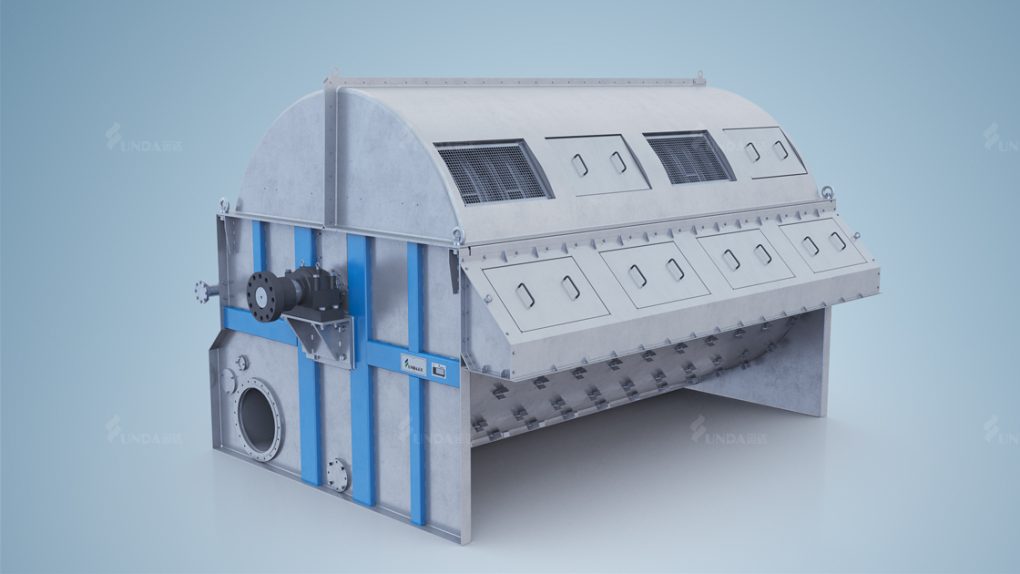

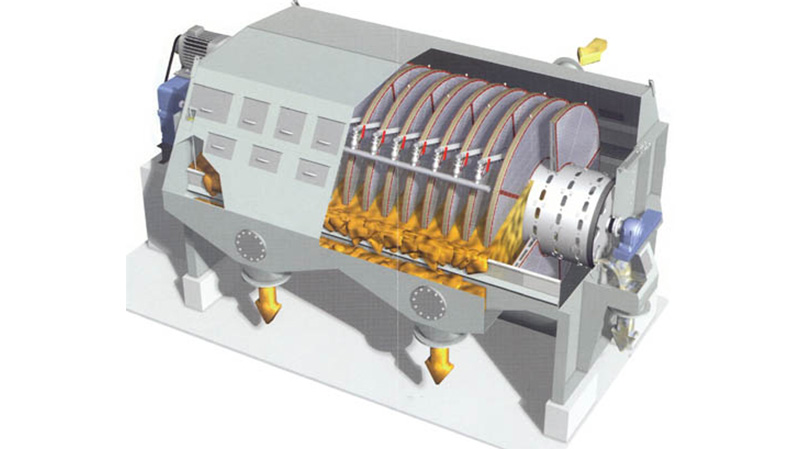

The machine is mainly composed of tank body, upper cover, main shaft, sector plate, web cleaner and drive device etc. The detailed structure is shown in the equipment general drawing.

- Tank body: the tank body consists of three parts: inlet tank, middle tank and outlet tank. The pulp enters into the thickener from inlet tank, continuously concentrated in the tank body and flows to the outlet tank, then discharged from the outlet tank by overflowing. The tank body adopts a forward flow structure, which is welded by steel plate and structural steel.

- Upper cover: it is welded by steel plate with a window set on the cover plate. Open the movable cover plate to observe the operation of each part. When to check or repair or to replace screen cloth, the cover can be removed by lifting lugs on the cover.

- Filter plate: the filter plate is composed of 8 stainless steel sector plates covering stainless steel screen cloth. The screen cloth is 40-60mesh. The sector filter plates are installed and connected with the outer of the main shaft through bolts, firmly constructed and conveniently installed.

- Screen cloth cleaner: through the ultra-thin self-cleaning nozzle on the spray pipe, the high pressure water of 0.6 ~ 0.7 MPa is sprayed to wash away pulp left on screen cloth surface and wash cloth, so as to restore the filtration function of the cloth. The two ends of the nozzle are both of G3” pipe threads, and washing position can be changed by rotating and adjusting the angle of the nozzle.

- The drive device is mainly made up of suspended solid shaft reducer, variable frequency motor with wheel, torque arm and so on. By adjusting the speed of motor, the filter plate speed of thickener can be adjusted to meet the technological requirements of concentration process.

Technical Parameter

| Model | ZNH25 | ZNH35 | ZNH45 | ZNH55 |

| Filter disk diameter: (mm) | 2500 | 3500 | 4500 | 5500 |

| Disk: (㎡) | 8.5 | 16.7 | 26 | 38 |

| Quantity of sector plate: (piece) | 12 | 14 | 16 | 18 |

Working site