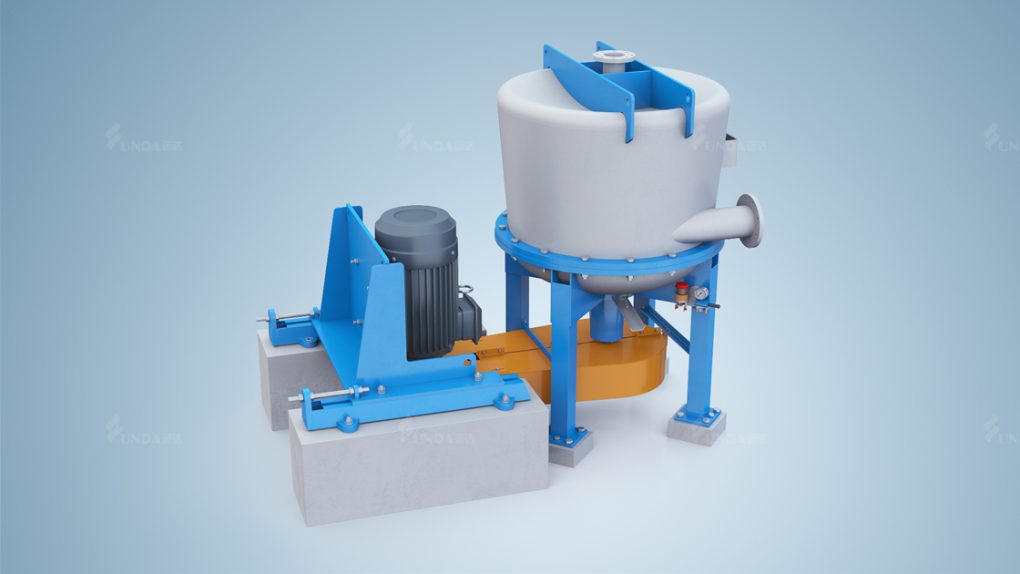

ZQF Float Purger is newly developed equipment to make waste paper pulp of high quality. Its functions are separating light and heavy impurities in waste paper pulp, secondary deflaking fiber, featuring high efficiency and energy saving. This machine is especially capable of removing the light impurities contained in the waste paper, collecting and removing the heavy impurities to clean the pulp.

Structure of Equipment

The float purger is mainly composed of shell, inlet and outlet pipe, screen plate, impeller and so on.

The shell of the float purger is a metal cone made from rolling and welding steel plate.

The inlet is located in the tangent direction on the side wall and at the upper part provided with light impurity outlet. The screen plate is installed at bottom part of the shell. Accepted pulp passes through the screen plate and then discharged through outlet pipe.

Rotating impeller is close to the screen plate, the clearance between the impeller and the screen plate is 1-3mm. The impeller is fixed to the spindle, which is supported by a rolling bearing and driven by motor through pulley.

Operating Principle

The pulp enters into the conical shell in the tangent direction and then revolves in spirals at high velocity under the inlet pressure and force of rotating impeller, then produces strong turbulence and hydraulic shear force.

The pulp is deflaked by hydraulic shear, fiber friction and impeller impact. Under the joint action of pressure difference on both sides of the screen plate and impeller pushing force, accepted pulp passes through the screen holes and then discharged from the outlet.

The pulp generates strong centrifugal force when rotating at high speed in the shell. Under the action of centrifugal force, heavy impurities in the pulp are separated and thrown into the outlet of heavy impurities along the inner wall of the shell. The light impurities have a small specific gravity and are concentrated in the center of the air core, then discharged continuously from the outlet of the light impurities at the center of the upper end. A small amount of fiber is mixed in the light impurities, which needs to be recycled by reject sorter.

Advantage

- Applied to handling kinds of waste paper (including low-level waste paper), installed in coarse screening system, especially used for handling heavy polluted long fiber. It helps reduce the cost by decreasing the pretreatment of raw materials.

- Condense the light contaminants and then remove them without reducing particle size

- Secondary deflaking of fiber and help remove heavy contaminants; decrease the deposition of contaminants in pulper thus to increase the producing capacity

- Shorten downtime

- Automatically wash the screen holes, help get high quality pulp, reduce fiber loss and enhance paper quality

Technical Data

| Model | ZQF2 | ZQF3 |

| Inlet Consistency (%) | 2.5-4 | 2.5-4 |

| Capacity (T/D) | 65-85 | 110-140 |

| Inlet Pressure (MPa) | 0.2-0.3 | 0.2-0.3 |

| Volume (m3) | 0.8 | 2 |

| Vane Wheel Dia. (mm) | 635 | 863 |

| Main Shaft Rotational Speed (r/min) | 800 | 500 |

| Motor Power (KW) | 55 | 110 |

| Screen Hole Dia. (mm) | φ5 | φ5 |

| Inlet and Outlet Dia. (mm) | 150 | 200 |

| Weight: (Motor Excluded) (Kg) | 2000 | 3800 |

Working site