Advantages

- The coarse contaminants after handling by this machine have less fiber and almost no water. Thus, help reduce handling cost in the following procedure.

- Low friction force due to special rotor design, almost no disintegration of contaminants, realize the high efficient separation of contaminants and pulp.

- Upper cover can be opened for simpler and easier maintenance.

- Equipped with washing pipe to reduce basket plugging and fiber loss.

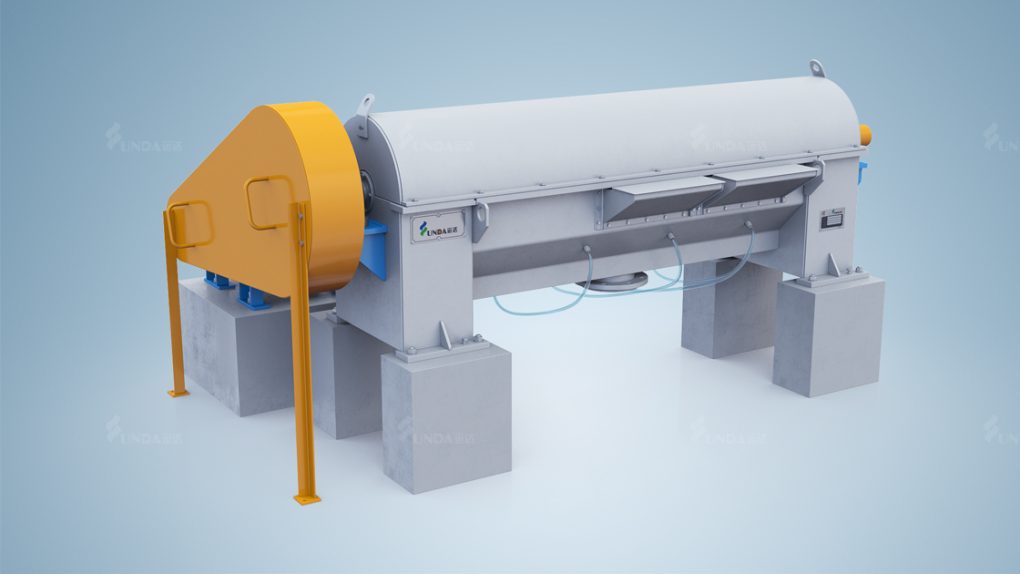

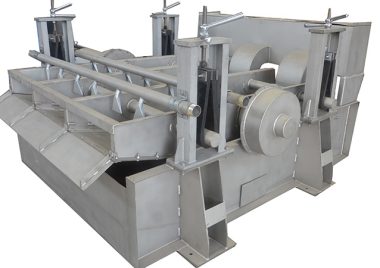

Structure and Principle

The machine comprises a welded assembly body, which supports screen plate, rotor, collecting tank, dregs drain and bracket. The machine is installed horizontally.

The machine is driven by belt. The belt pulley and belt can be installed at either end of the equipment and the motor is installed close to the equipment.

The rotor is a long cylinder structure holding vanes close to main body of the equipment. Angle of vanes is preset to optimal. The design of shaft enables the driving belt to be installed at either end of the equipment. The rotor is supported by bearing seats on both sides of the shell.

Easily dismantled cover of shell enables to repair internal components easily. The rotor or screen plate can be checked and repaired without removing the inlet pipe and belt pulley. The cover is provided with a baffle to prevent the slurry from axial return, and the rotor pushes the slurry forward.

The accept outlet groove and the reject discharge groove are both part of the overall structure. The accept groove, designed to increase the strength of the equipment, is used to collect the filtrate, the reject discharge groove is located on the landing leg opposite to the end of the inlet.

The screen plate with holes is semi-cylindrical, and the holes on the screen plate can be different according to working conditions. The screen plate is fixed to the shell with bolts.

Technical Parameter

| Model | ZSR3 |

| Nominal diameter (mm) | Φ400 |

| Capacity (t/d) | 25-45 |

| Inlet consistenc (%) | 1-1.5 |

| Reject consistency (%) | 15-30 |

| Power (kW) | 37 |

Working site