Advantages

- Screening by slotted cylindrical screen, higher efficiency

- Combined belt drive, stable operation, lower noise

- Fan-shaped spraying system, better light rejects screening

Working Principle info

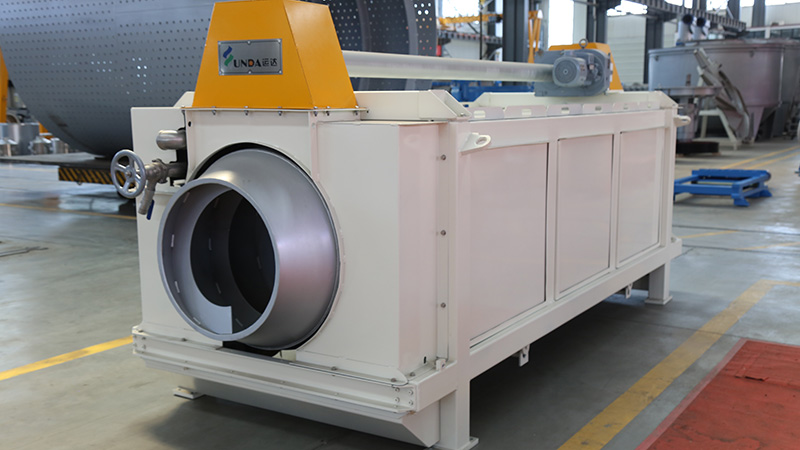

Composed of machine frame, cylinder, riding wheel device, transmission device, reducer, spray pipe, mobile cleaning hose device, pulp receiving plate and shield.

- The cylinder is supported by the riding wheel fixed on machine frame and rotates under driven by transmission device through combined belt drive.

- After entering rotating cylinder and washed from spray pipe, fibers in the feed will be brought out by water and discharged as accepted pulp through screen slots. Remaining materials will be discharged as tail rejects.

- Under control of servo drive, cleaning hose continuously cleans every screen slot so that the screening section of cylinder can continuously runs without plugging.

Technical Parameter

| Model | Cylinder Diameter(mm) | Effective Screen Length (mm) | Rated Power (KW) | Spray Water Throughput (0.3Mpa, L/Min) | Cleaning Tube Water Throughput (1.5Mpa,L/Min) | Inlet and Outlet Diameter(DN) |

| WTK85A | 850 | 2000 | 3 | 150 | 50 | 250 |

| WTK85B | 850 | 3000 | 3 | 280 | 76 | 250 |

| WTK150A | 1500 | 3000 | 15 | 660 | 280 | 400 |