In general, paper and board are easily re-usable after their manufacture. This is daily practice in paper mills by re-using dry broke from finishing operations and off-quality paper. Exceptions are special characteristics like wet-strength paper and the like. On its further path, paper and board gets converted by applying coating colours, inks, varnishes, laminates, adhesives and other substances to final paper and board products being sold, used and hopefully recovered and returned back into the next recycling life cycle. So, recycling is process-related and describes the reuse of paper for recycling within the paper and board industry to manufacture new paper and board grades.

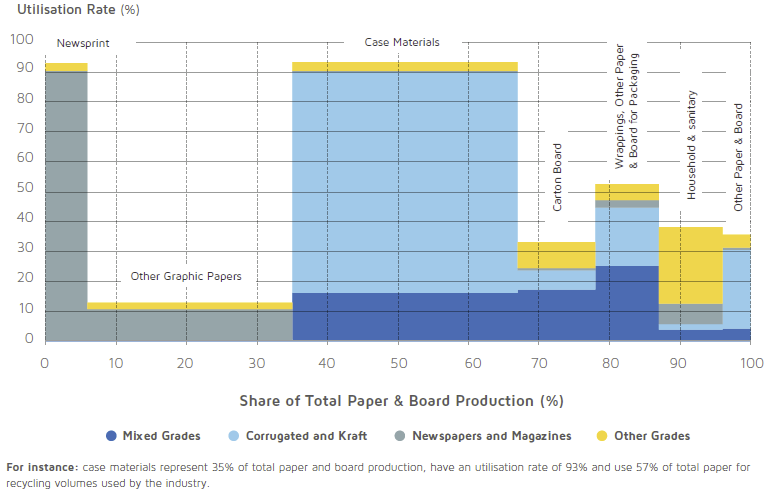

Recyclability is product-related and describes the ability to reuse a specific paper or board product within the paper and board industry to produce new paper or boards grades. The better the recyclability the easier is the re-use of the paper product. A good recyclability of each paper product is important especially for the two large paper and board categories graphic papers and packaging papers and board. They comprise about 85 % of the total paper and board production in the CEPI countries and by far they are the largest consumer of paper for recycling (Figure 1). So, the majority of paper and board manufactured comes back to the paper industry in the form of used paper and board products. A recyclability test should justify that a paper product is able to be recycled in typical standard processes without creating significant problems and/or disproportionate losses.

However, a recycling process is even possible for paper products which do not pass a standard recyclability test. For example, liquid packaging products are removed as reject in an industrial paper for recycling process and typically do not pass recyclability tests because due to the both-sided polyethylene layer water is not able to penetrate into the fibre network. But specially equipped industrial processes can handle even these products by pre-cutting the liquid packages. The disadvantage is that liquid packaging material has to be collected separately or separated from the enclosed material stream. In Germany, liquid packaging is collected in the material stream “light packages” together with yoghurt cups, plastic bottles for cosmetics, bags for soap or sauce, metal tins, food dishes etc. from which they can be separated easily and reused in specially equipped paper mills.

However, recyclability is not a necessary requirement for each paper product. About 15 % of the paper industry’s production (Figure 1) is related to household and sanitary as well as other paper grades, comprising technical and special paper grades. Those paper grades end up in the sewage water system (e.g. toilet paper), are part of another product (e.g. decor paper as part of furniture or laminate floor, capacitor paper), residual waste (e.g. used tissue handkerchief, tea bags, oil or air filters, mustard paste tube) or simply burned (e.g. cigarette papers) and withdraw from the recycling process.

During recovery, collection and sorting paper for recycling might be contaminated unintentionally with non-paper components and unwanted material. These materials are limited by weight for each grade of paper for recycling in the EN 643 (European List of standard grades of paper and board for recycling).2 The industrial installed paper recycling processes should be able to handle the tolerable amount of non-paper components and unwanted material. Additionally, the industrial process has to cope with those materials which are added finally since paper manufacturing to achieve a final paper or board product. According to EN 643 these materials are not any longer a non-paper component, even when it is an adhesive application for producing a paperback or a folding box. Only foreign matter in grades of paper and board for recycling, which is not a constituent part of the discrete paper or board product and which can be separated by dry sorting, belongs by definition of EN 643 to the non-paper components. This assumes that industrial recycling processes can handle the amounts of non-paper components and unwanted materials coming with the paper for recycling grades into the paper mills. The reverse conclusion is that arising problems in the mills nowadays and in the future are dominated by an insufficient recycling-friendly design of the paper and board products. A recycling-friendly design is not self-evident because the wrong adhesive or printing ink always can be used for manufacturing a paper or board product. The term “recyclability” is always related to a single specific paper or board product and never to a grade of paper for recycling. To prove recyclability the description of a test method, the characteristics to be determined and the definition of target and threshold values are also necessary. Today, very often a paper product is named as “recyclable” without explaining how it was tested.

The European Declaration on Paper Recycling 2016-2020 defines the term “Recyclability” as: “Design, manufacturing and converting of paper-based products in such a way as to enable a high quality recycling of fibres and other materials in a manufacturing process in compliance – where appropriate – with current standards in the European Union.3 The expression “high quality recycling” implies the claim that recycling should be possible at the same quality level. The Declaration does not name details, but there are spin-off documents like Guidelines or Scorecards which take care of technical details and specifications.

Source: https://forestbiofacts.com/

Case

-

Five Continents Special Paper 450,000 tons packaging paper Project

Five Continents Special Paper 450,000 tons packaging paper Project

-

The i-CTMP High Yield Pulping Production line of Shan Ying

The i-CTMP High Yield Pulping Production line of Shan Ying

-

Shandong Tianhe i-BCTMP pulping line upgrade project

Shandong Tianhe i-BCTMP pulping line upgrade project

-

Guangxi Sun Cultural Paper

Guangxi Sun Cultural Paper

-

Qianan Boda Cultural Paper

Qianan Boda Cultural Paper

-

Vietnam Thuận An Paper PM8 Project

Vietnam Thuận An Paper PM8 Project

-

EG-Paper Packaging

EG-Paper Packaging

-

400t/d Bamboo Fiber i-CTMP Project

400t/d Bamboo Fiber i-CTMP Project

-

Guangxi Kebao ZDG425 Drum Pulper

Guangxi Kebao ZDG425 Drum Pulper

-

The Rebuild of IKPP OCC Line

The Rebuild of IKPP OCC Line