i-VSP

Virgin Pulp Stock Preparation & Tissue Paper Making Line

Applications:Facial Tissue,Napkin,Roll Tissue,Handkerchief Paper,Paper Towel,Sanitary,Napkin/Pad,Cotton Tissue Packing Paper.

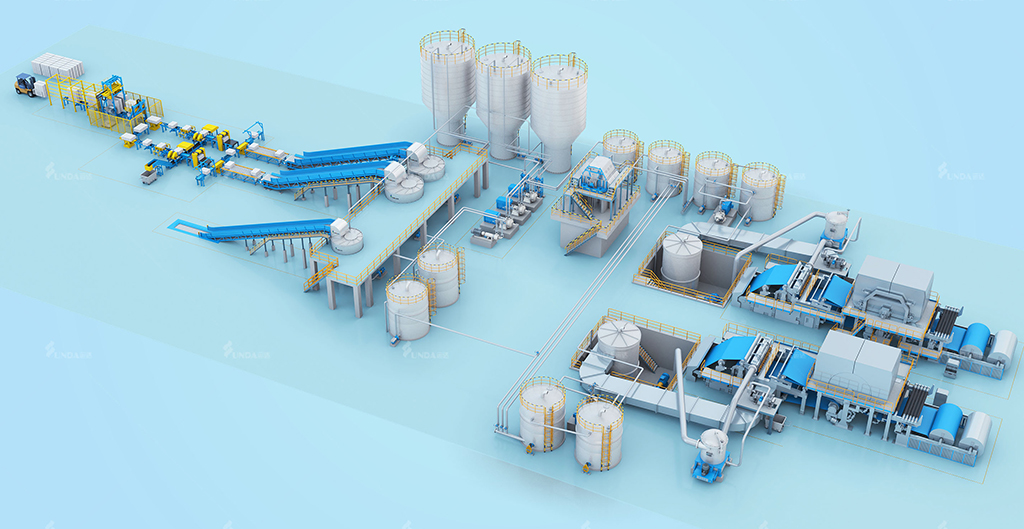

Yunda can provide you with a complete production line of tissue paper equipment. Our design considers the function of each part from stock preparation to packing so as to better ensure the smoothness and efficiency of our paper production equipment.

i-TSP: Excellent Tissue Machine Stock Preparation Solution

As a stock preparation system supplier, Yunda provides systematic solutions for the tissue machines and has supplied as much as 86 stock preparation and approach flow systems to different customers all over the world in between 2016 and 2022. Yunda i-VSP stock preparation has superior performance in reducing energy consumption, controlling product cost, improving product quality and operation stability.

Virgin Paper Pulping System

Pulp bales go firstly to the auto de-wiring machine with a conveyor from where the wires will be cut and removed automatically, after that they go into the mid-consistency pulper, under the mechanical force and hydraulic force generated by the rotating rotor the bales will be fully slushed into a constant consistency and will be then fed into the dump tower through a discharge pump.

Pulping process can either be in a batch way or in a continuous way. In the dump tower pulp will be well swelled and then it goes to the refining system for the development of the fiber strength. HD Cleaning and magnetic separation will be need before entering the refiner to remove the heavy and hard contaminants and protect the refiner plates. After the refining process with required beating degree the pulp will be then fed into the final storage tower. Afterwards in the mixing process different furnishes will be dosed into the mixing chest automatically as per the setting, from the mixing chest the mixed pulp travels through a mixing refiner, machine chest, fan pump, screen and finally reaches the headbox.

Case

Heng’an Group Paper

Project name: Hubei Hengan Tissue Paper

Annual Capacity: 100,000 tons

Paper type:High-grade Tissue Paper

Raw material: UBKP, LBKP

In July 2023, Hengan (China) Hubei T31/33 project PM31 paper machine started up smoothly. Yunda supplied stock preparation and approach flow system equipment,including chain conveyor for pulpe bales,high density cleaner, PM double disc refiner, NLS flow screen, broke pulper, etc. The 3600mm width new-moon type tissue machine of this project is supplied by TOSCOTEC, The reliable quality of Yunda stock preparation equipment ensures the smooth runnability of this tissue machine and the high quality of the product.

i-VSP Stock Preparation System Advantages :

Different fibers are processed separately

Long fiber, short fiber, and broke are processed separately in the i-VSP Tissue Machine Stock Preparation System, which has the following advantages:

- High system efficiency

- Low energy consumption

- Good bulk of Final Paper

- Good strength index of Final Paper

Intelligent Pulping Control + High Efficient Pulping Equipment (Pulping Energy Consumption-reduced by 30% )

- New S-type Middle Consistency Rotor

- Intelligent Pulping Control System

- Bale Breaker design inside the Pulper Vat

The System: Automation、Intelligent Design

With group start/stop, self-diagnose and functioning of different sensors, the system has the following advantages:

- Avoid mis-operation and reduce system failures when it is running.

- Pulping level and feeding amount are automatically controlled.

- Pulper motor is equipped with frequency converter and the speed is controlled automatically according to the requirements of the pulping process.