The recycling of paper and board products such as printed material, folding boxes, polyethylene coated liquid containers, or envelopes with pressure sensitive adhesives and transparent windows has decisive importance for improving the use of paper for recycling. In this context, good recyclability refers to the easy processing of the secondary fibre raw material into a new paper. Materials added to paper and board such as printing inks or adhesives should be benign during paper for recycling processing and not affect water loops, paper production and paper converting. The processing residues (rejects and sludges) enriched with non-fibrous components should not be harmful to the environment and offer possibilities for suitable use in other industrial processes, energy recovery, or final disposal by landfilling.

The term “non-paper components” in paper for recycling trade and quality control according to EN 643 is used for material other than paper products which is not a constituent part of a paper or board product and which can be separated by dry sorting.1 The content of non-paper components therefore is mainly dependant on collection, handling and sorting. But of course, there can be non-fibrous materials attached to a paper or board product which are by definition not non-fibre components. They should be named “non-fibre product component”. Examples of graphic paper products are laminated covers, staples in magazines, adhesive applications on catalogues or books, or samples of cosmetics and the like in magazines. For packaging paper and board products examples are adhesive applications or staples on boxes, dispersion coatings or laminates of plastic films, wet-strength finishing or plastic tapes for sealing boxes. Paper for recycling treatment plants are designed to handle a certain amount of those unusable components coming from the paper for recycling and from the paper/board products. If the amount rises too high, the treatment process becomes less economic due to higher raw material demand because of lower yield and higher costs for disposal and wear and tear of equipment as well as less ecological benefit due to higher reject rates and energy requirements.

For all paper recycling processes it is essential that the paper products can be repulped. Paper is not water-resistant unless specially treated. Besides papers with wet-strength features, paper for recycling is relatively easily repulpable in aqueous conditions by applying sufficient mechanical energy. Wet-strength features are necessary for certain packaging papers, some specialty papers like labels and a part of hygiene papers, e.g. kitchen towels. In these cases either the paper manufacturer or the converter applies a wet-strength agent or a protective coating in or on the paper or board. To recycle these paper products more energy during pulping and/or dedicated chemical conditions or special processes are required. EN 643 contains several paper for recycling grades which might be considered not repulpable under standard conditions. Therefore, these grades are listed under “Special Grades (Group 5)”.1 A special recyclability test procedure for those paper products does not yet exist.

White and unprinted paper for recycling originates from converting processes and is very limited in quantity. Most of the recycling processes producing white and clean pulps therefore have to remove inks and toners. The deinking process has become one of the key technologies of paper for recycling treatment plants for the production of graphic papers, sanitary papers and even white top plies of testliner or board. For graphic paper products the optical properties after the recycling process in the so-called “deinked pulp (DIP)” are an essential quality requirement. The deinkability of printed paper products, its assessment and the factors influencing deinkability are discussed in the separate articles: Deinkability test methods and EPRC deinkability assessment.

The production, converting and use of a recycled product is only successful if no troubles with adhesive applications occur. It is common sense that adhesive applications in the recycling process should be removed as completely as possible from the pulp. Therefore, the screening ability of adhesive applications is the main criterion for the recyclability of paper products. For details see separate article “Removability of adhesive applications“.

Paper and board intended for food contact must not bear any risks for the consumer’s health. Therefore, there is a certain regulation in place. Using paper for recycling in paper and board for food contact means also using only paper for recycling from controlled and clean sources. There are some paper for recycling grades which are excluded for the production of paper and board for food contact. Furthermore, special food contact regulations also define additives which are allowed in paper and board production.

Relevance of recyclability

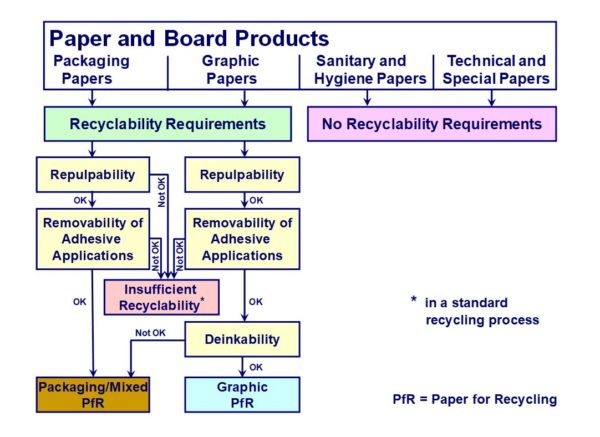

The term recyclability is related to a specific paper product as already mentioned. Assuming that the grade of paper for recycling and the installed recycling process fit to the paper or board grade to be produced, recycling should be not problematic from the theoretical point of view if each single paper product within the utilised paper for recycling has a sufficient recyclability behaviour. In this case, the challenges in the recycling process would be dominated by the non-paper components and the unwanted material introduced in the process by the paper for recycling. But the more paper products are recovered and returned in the recycling loop and the more paper for recycling is required for production of all paper and board grades by the paper industry the more important becomes the recyclability behaviour of each paper or board product. Unfortunately, a common demand on recyclability criteria for different paper or board products does exist only to a limited extent. Only with standardised test methods, definition of relevant parameters and minimum quality levels to be obtained, an assessment will be possible for a good or acceptable recyclability of a paper product. Without test methods and evaluation procedures it cannot be expected that other parties of the paper chain will endeavour to develop better recyclable paper and board products. Related to paper consumption statistics (CEPI 2018)1 four paper and board product categories exist – two large and two smaller ones:

54 % Packaging paper and board

32 % Graphic papers

9 % Sanitary and household papers

5 % Other Papers (also called technical and special papers).

Consumption figures are presented here, because they represent the volume of paper products in the various paper for recycling grades. The dramatic shift from graphic paper to packaging paper and board consumption is documented by comparison of the CEPI figures with the year 2000 in which the consumption of graphic papers was still 49 % and of packaging paper and board only 41 %. Consumption behaviour of the society has completely reversed and can be expressed by the keywords e-commerce and e-paper. It is also documented by a reduction of paper consumption by 6 % in the CEPI countries since 2000.2

The dominating production and consumption of graphic papers in the past and the development of new printing technologies were the reasons that, in the context with recyclability, greater efforts were made in developing criteria for deinkability of printed products. INGEDE, the International Association of the Deinking Industry, founded in 1989, launched very early research projects in the development of test methods of printed graphic paper products. The point of origin was the situation that graphic papers based on secondary fibres have to be produced from graphic grades of paper for recycling with a deinking process for the removal of the printing ink. The detachment of ink particles from the paper surface and their removal by flotation is essential for a sufficient recycling process to manufacture, once again, new graphic papers such as newsprint, SC or LWC grades. At the time, it was already well known that depending on the printing process, the used printing ink and paper quality, as well as the chosen deinking conditions, the results of a deinking process can differ significantly. It was the success of INGEDE to establish very early a standard deinking procedure to compare different print products and their deinkability behaviour. In 2020, the ISO 21993 has become an international standard for the deinkablity of printed paper products.3

For the recyclability evaluation of a printed graphic paper product it becomes evident from Figure 1 that two tests are relevant: deinkability and removability of adhesive applications. The latter case is only evaluated if the printed paper product has an adhesive application. This is the only test which ends up in an insufficient recyclability if the adhesive application attached to the printed product cannot removed sufficiently. Insufficient deinkability does not lead to the judgement not recyclable, because the print product still can be used in recycling processes without deinking and it can therefore enter packaging or mixed paper for recycling grades. If adhesive applications are removed sufficiently and the deinkability of a print product is at least acceptable, it can enter the graphic paper for recycling grades. Repulping is a prerequisite for both tests of graphic paper products, but typically unproblematic. Therefore, no criteria exist for how much un-defibred material is accepted.

The second large category is packaging paper and board products mainly manufactured from corrugated board and folding boxboard. Typically, those products are brown or grey or have at least one grey or brown ply within the board. Therefore, deinkablity is not a requirement for the recyclability of these products. Due to the fact that in this product category paper or board strength plays a more important role than in graphic paper products, sometimes the papers are finished as wet-strength material or the board is laminated with plastic, the repulpability becomes more difficult. Test methods have to define the acceptable material volume which might be not repulpable. The removal of adhesive applications (if existing) from packaging products is also of interest and may lead also to an insufficient recyclability. In this product area no common agreement exists for good recyclable paper products. Different research projects and national approaches so far have not lead to a uniform acceptance for recyclability tests of packaging paper and board products. At the moment, an international expert group is working on this subject and this is the reason that this category is not discussed further in this chapter. For the two other paper and board product categories, sanitary and household papers as well as technical and special papers, no recyclability requirements exist. They have, at least, no relevance if the produced products are not intended to enter the paper recycling circuit like toilet papers, cigarette papers or filter papers.

Source https://forestbiofacts.com/

Case

-

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

Yunda Supplies High-Consistency Refiner S2070 Drive Assembly to JSC, Belarus

-

Russia Khargi Packaging Paper Project

Russia Khargi Packaging Paper Project

-

350,000 tpy Linerboard Project in Arkhangelsk, Russia

350,000 tpy Linerboard Project in Arkhangelsk, Russia

-

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

KOA Vietnam 6600/1100 Packaging Paper Upgrade Project

-

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

Smooth Shipment of Complete Thermo Mechanical Pulping Equipment for Thailand Precise Molding Project

-

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

Successful Delivery of the Refiner Repair Project Between Yunda and Guangzhou Paper Group

-

100,000 Tons Per Year Cultural Paper Project in Ethiopia

100,000 Tons Per Year Cultural Paper Project in Ethiopia

-

Taison (Guizhou) 160,000 tons tissue paper project

Taison (Guizhou) 160,000 tons tissue paper project

-

Taison Tissue Paper Project

Taison Tissue Paper Project

-

Guangxi Xiongfu Paper Project

Guangxi Xiongfu Paper Project